Qualipak machinery is a packaging equipment manufacturer of coffee packaging machines for the operations that follow the primary packaging. We can offer a turnkey solution for your ground or whole bean coffee packaging applicationOur machines are perfectly adapted to handle coffee jars, coffee pouches, coffee pods, etc.

Whether your coffee product is packaged in a pouch, a jar, a pod or any other type of container, Qualipak can help you automate your secondary and tertiary packaging operations. Its customizable design allows you to adapt the speed of the equipment to your production needs.

According to different coffee products, our Bagger can work with different single dose filling system to form pillow bag, 3/4 side sealed bag, gusset bags, flat bottom bags, premade bag, doypack bag and more.

Ground Coffee Powder Packaging Machine with auger filler

Usage of coffee powder packaging machine:

This machine is widely used to pack powder products: such as coffee powder, spices, curry powder, protein powder, milk powder, flour, starch, condiment, herbal powder, chemical and medical powder products.

Features of auger filler:

1. Screw driven by servo motor, speed can be set, stable performance, accurate measurement

2. Well known Touch screen in both English and Chinese, operation simple and intuitive

3. CPU control system USES the independent property rights

4. Open cutting type transparent material box, easy to observe, convenient cleaning

5. Adopt The domestic and international famous brand spare parts

6. Optional to add dust removal mechanism, make work environment clean.

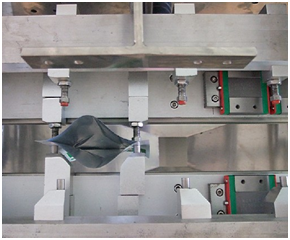

Features of bagging machine:

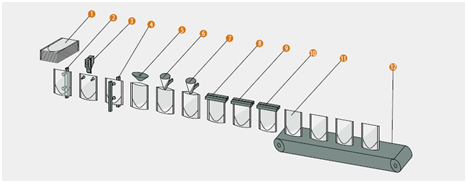

√ 1.This machine can automatically complete material lifting--auger filler measuring--coding--bag making--filling--sealing--counting--conveying finished products--sorting finished products.

√ 2. Siemens Touch screen/PLC can store a variety of different product packaging process parameters, when replacement product, it can be used at any time without having to reset.

√ 3.Equipped with fault display system, when the fault occurs, be clear at a glance, in order to promptly eliminate.

√ 4. Can make hole punching device after customer's request.

√ 5. Whole machine is made of 304 stainless steel.

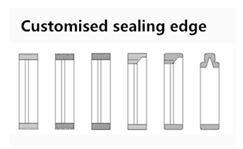

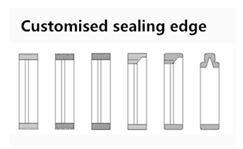

√ 6. Optional to packing Pillow bag , punching bag, gusseted bag, vacuum bag etc.

√ 7. Servo motor driven film pulling, accurate, reliable and stable

√ 8. Suitable for laminated film such as paper/PE, PET/PE, PP/PE, aluminum foil based

√ 9. Easy to change the bag former for different width bags

Parameters of coffee bagging machine:

| Model | ZVF-260 (Other model ZVF-200, ZVF-350 ) |

| Bag Type | Pillow Bag, Gusseted Bag, Block Bottom Bag |

| Product Characteristic: | Powders |

| Dosing System Compatible: | Auger Filler |

| Measuring range | 50-1000 g (transform spiral accessories) |

| Measuring accuracy | ≤ 100 grams deviation ≤±2% ;100-500 grams deviation ≤±1%; |

| ≥ 500 grams deviation ≤±0.5%; | |

| Control By | PLC with HMI Touch Screen |

| Running Motion: | Intermittent |

| Speed | 50-100 bags/min |

| Bag Length | 50 to 340mm (2.0 to 13.4") |

| Bag Width | 80 to 260mm (3.1 to 10.3") |

| Film Width | ≤540mm |

| Film Thickness | 0.04-0.12mm |

| Reel Outer Diameter | Ф450mm |

| Core Inner Diameter | Ф75mm |

| Power Supply | Or per customer's specification |

| Power Consumption | 3KW |

| Air Source | 0.6MPa,0.36 M3 /min |

| Machine Dimension | 1745x1217x1680mm (L x W x H) |

| Machine Weight | 800KG |

Below are some others type coffee packaging machines, pls feel free to contact us if you need more details informations:

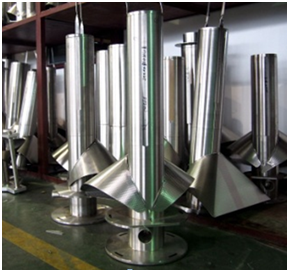

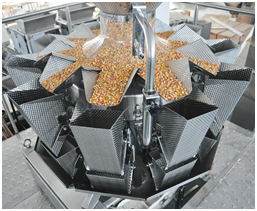

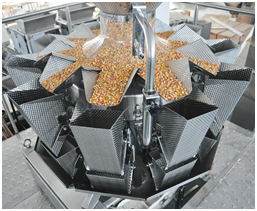

Roasted Coffee Beans Packaging Machine with multi heads weigher for premade pouch

This machine are consist of multi heads weigher and horizontal type premade pouch packaging machine, it is used to pack granule products: such as coffee beans, nuts, snacks, candys etc.

1) Material conveying, weighing, filling, bag-opening, date-printing, finished product outputting are all completed automatically.

1) Material conveying, weighing, filling, bag-opening, date-printing, finished product outputting are all completed automatically.

2) High weighing precision and efficiency.

2) High weighing precision and efficiency.

3) Packing efficiency will be high with horizontal packing machine and easy to operate.

3) Packing efficiency will be high with horizontal packing machine and easy to operate.

4) The premade pouch can be with zipper or without zipper.

5) The packing speed can up to 50 bags/min max.

4) The premade pouch can be with zipper or without zipper.

5) The packing speed can up to 50 bags/min max.

1) Material conveying, weighing, filling, bag-opening, date-printing, finished product outputting are all completed automatically.

1) Material conveying, weighing, filling, bag-opening, date-printing, finished product outputting are all completed automatically.

2) High weighing precision and efficiency.

2) High weighing precision and efficiency.

3) Packing efficiency will be high with horizontal packing machine and easy to operate.

3) Packing efficiency will be high with horizontal packing machine and easy to operate.

4) The premade pouch can be with zipper or without zipper.

5) The packing speed can up to 50 bags/min max.

4) The premade pouch can be with zipper or without zipper.

5) The packing speed can up to 50 bags/min max.

Instant Coffee stick packing machine

This Automatic Multi-lines Packaging Machine is suitable for packing of granular of medicine, food and chemical products, powder and water-bindered pills, etc. Such as medicine granular, sugar, plant seeds. Silica gel, tea, etc.

√ According to different packing speed, we can provide 4 lanes or 6 lanes or 8 lanes packaging machine.

√ All the parts contacting with product is made of 304SS. And this machine is completely closed when running, which meets to GMP standard by pharmacy.

√ According to different packing speed, we can provide 4 lanes or 6 lanes or 8 lanes packaging machine.

√ All the parts contacting with product is made of 304SS. And this machine is completely closed when running, which meets to GMP standard by pharmacy.

√ Quick format change with few tools.

√ High performance, accuracy and reliability: OEE > 95%.

√ Systems for transfer to secondary packaging equipment.

√ Free access to main components for cleaning (Tool-free).

√ Flexible and compact design suitable for any product (granular, pieces, liquid or powder).

√ Packing speed of per lane is 30-50 bags/min/lane

√ Quick format change with few tools.

√ High performance, accuracy and reliability: OEE > 95%.

√ Systems for transfer to secondary packaging equipment.

√ Free access to main components for cleaning (Tool-free).

√ Flexible and compact design suitable for any product (granular, pieces, liquid or powder).

√ Packing speed of per lane is 30-50 bags/min/lane

√ According to different packing speed, we can provide 4 lanes or 6 lanes or 8 lanes packaging machine.

√ All the parts contacting with product is made of 304SS. And this machine is completely closed when running, which meets to GMP standard by pharmacy.

√ According to different packing speed, we can provide 4 lanes or 6 lanes or 8 lanes packaging machine.

√ All the parts contacting with product is made of 304SS. And this machine is completely closed when running, which meets to GMP standard by pharmacy.

√ Quick format change with few tools.

√ High performance, accuracy and reliability: OEE > 95%.

√ Systems for transfer to secondary packaging equipment.

√ Free access to main components for cleaning (Tool-free).

√ Flexible and compact design suitable for any product (granular, pieces, liquid or powder).

√ Packing speed of per lane is 30-50 bags/min/lane

√ Quick format change with few tools.

√ High performance, accuracy and reliability: OEE > 95%.

√ Systems for transfer to secondary packaging equipment.

√ Free access to main components for cleaning (Tool-free).

√ Flexible and compact design suitable for any product (granular, pieces, liquid or powder).

√ Packing speed of per lane is 30-50 bags/min/lane

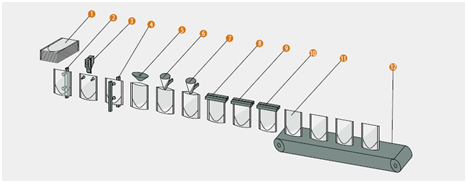

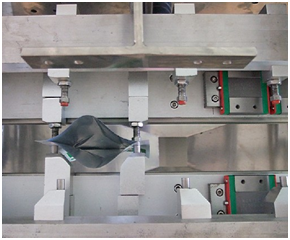

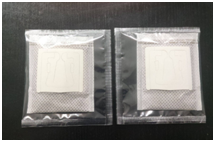

Drip Coffee Packaging machine

Drip Coffee Packaging machine is suitable for inner and outer bag packaging for tea leaves, herbal tea, health care tea, coffee, roots, and other small granule products.

√ Packing materials can be Paper/Plastic, Plastic/Aluminum/Plastic, Paper/Aluminum/Plastic, Drip coffee filter paper.

√ Outer bag sealing controlled by the stepper motor, bag length positioning is accurate and stable.

√ Adopts PID temperature controller for more accurate temperature adjustment.

√ Adopts PLC control system, human-machine interface, it is very easy to operate.

√ All parts in direct contact with products are made of SUS304 stainless steel, ensuring reliable products output conforming to food sanitary standards.

√ Some parts of the cylinder are imported, ensuring the accuracy and stability of performance.

√ Optional devices: flat cut device, date printer, easy tear device, etc.

√ Packing volume from 1-15g

√ Packing speed is 30-60 bags/min.

√ Packing materials can be Paper/Plastic, Plastic/Aluminum/Plastic, Paper/Aluminum/Plastic, Drip coffee filter paper.

√ Outer bag sealing controlled by the stepper motor, bag length positioning is accurate and stable.

√ Adopts PID temperature controller for more accurate temperature adjustment.

√ Adopts PLC control system, human-machine interface, it is very easy to operate.

√ All parts in direct contact with products are made of SUS304 stainless steel, ensuring reliable products output conforming to food sanitary standards.

√ Some parts of the cylinder are imported, ensuring the accuracy and stability of performance.

√ Optional devices: flat cut device, date printer, easy tear device, etc.

√ Packing volume from 1-15g

√ Packing speed is 30-60 bags/min.

√ Packing materials can be Paper/Plastic, Plastic/Aluminum/Plastic, Paper/Aluminum/Plastic, Drip coffee filter paper.

√ Outer bag sealing controlled by the stepper motor, bag length positioning is accurate and stable.

√ Adopts PID temperature controller for more accurate temperature adjustment.

√ Adopts PLC control system, human-machine interface, it is very easy to operate.

√ All parts in direct contact with products are made of SUS304 stainless steel, ensuring reliable products output conforming to food sanitary standards.

√ Some parts of the cylinder are imported, ensuring the accuracy and stability of performance.

√ Optional devices: flat cut device, date printer, easy tear device, etc.

√ Packing volume from 1-15g

√ Packing speed is 30-60 bags/min.

√ Packing materials can be Paper/Plastic, Plastic/Aluminum/Plastic, Paper/Aluminum/Plastic, Drip coffee filter paper.

√ Outer bag sealing controlled by the stepper motor, bag length positioning is accurate and stable.

√ Adopts PID temperature controller for more accurate temperature adjustment.

√ Adopts PLC control system, human-machine interface, it is very easy to operate.

√ All parts in direct contact with products are made of SUS304 stainless steel, ensuring reliable products output conforming to food sanitary standards.

√ Some parts of the cylinder are imported, ensuring the accuracy and stability of performance.

√ Optional devices: flat cut device, date printer, easy tear device, etc.

√ Packing volume from 1-15g

√ Packing speed is 30-60 bags/min.