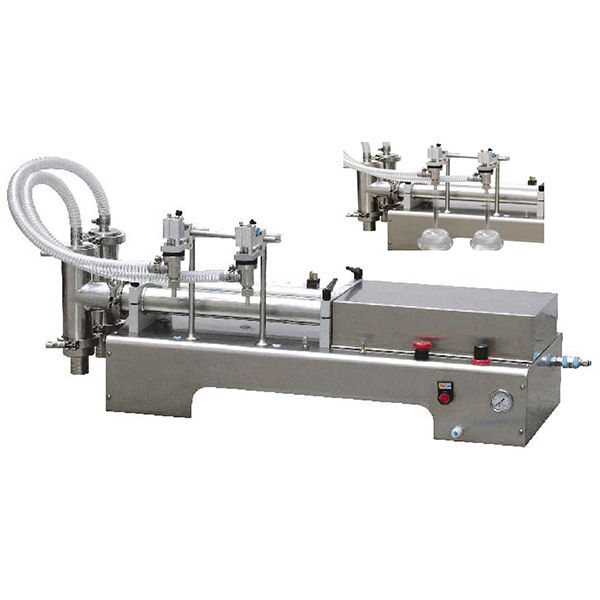

volumetric cup dosing filling machine food,doser

Application

The Volume Cup Filling machine good in measuring and filling free flow granular ,like rice, nuts, dry fruits, plastic piece, etc. It also can be for free flow powder, such as seasoning, fine salts, etc. It can connect with Horizontal Packing machine and Vertical Packing machine (FFS). After adding the Pedal button, it even can work for Pre-made bags / Perform Pouch, Bottles, jars and else containers.

Features

1. Single cup or 4/6 cups can be selected. 2. Machine frame can be Full stainless steel or Painted mild steel. 3. Cup(s) made by stainless steel or Nylon. 4. Cups fil...